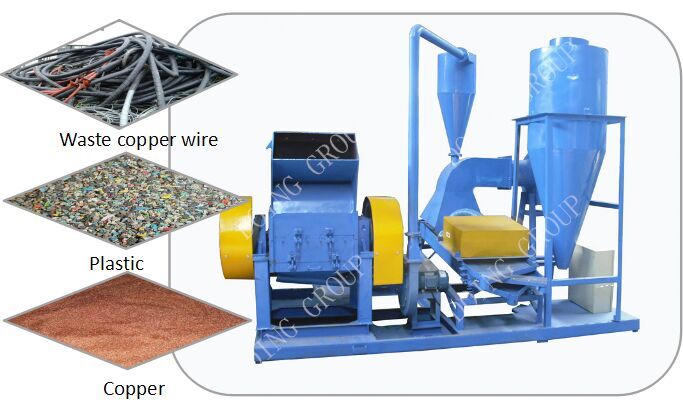

Due to its high electrical conductivity and corrosion resistance, it is suitable for motors and wires, pipe devices, heating elements and electronic devices. The global demand for copper is still very large. The data shows that the cost of extracting new copper resources is much higher than that of recycled copper. Therefore, the recycling of used copper can bring huge economic benefits to us. From the perspective of environmental protection, the recycling of scrap copper is also a meaningful part of our living environment. Things. The DoingGroup's copper wire recycling machine is the use of copper and plastic separation machinery scrap copper crushing, the recovery process involves several key steps, the understanding process may encourage people to maximize recycling.

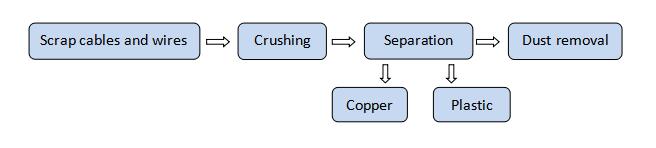

The first step: Collect

Collecting copper is the first step in recycling. Can collect a variety of waste miscellaneous lines, scrap copper-plastic line, fine wool, copper-plastic composite line, aluminum-plastic line, sheath line, and other copper-containing waste line.

The second step: Broken

The recycled scrap copper wire was put into the DoingGroup's copper wire recycling machine. After the process of crushing, removing iron, and crushing, the scrap copper wire was processed into a grain size, which was also called a copper-rice machine.

The third step: Sorting

The copper and plastic broken into the size of the rice are sorted according to the specific gravity and separated from the electrostatic separation process. This is a completely dry physical separation, and the entire process avoids the traditional “fired copper” and “gouache”. "Washing copper" is an environmentally unfriendly way of recycling. Double recycling of plastics and metals, comprehensive utilization

The fourth step: Dust removal

Dispose of the dust generated during operation. Guaranteed zero emissions to the environment.

Since the properties and functions of copper do not change with continuous processing, it can be used repeatedly without changing its performance. These properties make recycling copper very advantageous, and the copper wire recycling machine and industry is very profitable and prosperous.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.continuouspyrolysisplant.com