Continuous processing of tire pyrolysis plant

Bacth tire pyrolysis plant, the successful mitigation of the energy crisis and environmental hazards. However, for some large and medium sized refineries and workshops, the efficiency of bacth tire pyrolysis plant is not very satisfactory. DoingGroup developed a continuous tire pyrolysis plant for this problem.

Continuous tire pyrolysis plant workflow is:

1. Collect waste tires.

2 with a wire drawing machine out of waste tires in the wire.

3. Use a tire crusher to break the tire from which the wire is pulled into pieces of 3-5 cm.

4. The broken tire block, into a continuous tire cracker, after multi-stage pyrolysis reactor pyrolysis oil and gas. Oil and gas are cooled to liquid oil through the cooling system.

5. The residue (carbon black) will be continuously discharged into the tire's carbon black dispersion system.

The reason why the continuous tire pyrolysis plant is the upgrading of batch tire pyrolysis plant, mainly because it has the following advantages:

1. Use PLC control system to save manpower and improve equipment operation efficiency.

2. Realized 24 hours, continuous feeding, continuous slagging, increase oil yield.

3. Indirect hot air heating and wire premature withdrawal, can reduce the damage to the reactor, thus ensuring a longer service life.

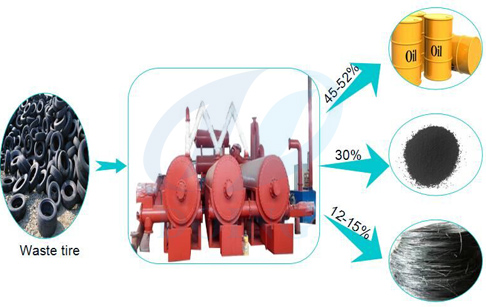

The main products of continuous tire pyrolysis plant are fuel oil, carbon black, steel wire and combustible gas. Their main uses are as follows:

Fuel oil usage

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

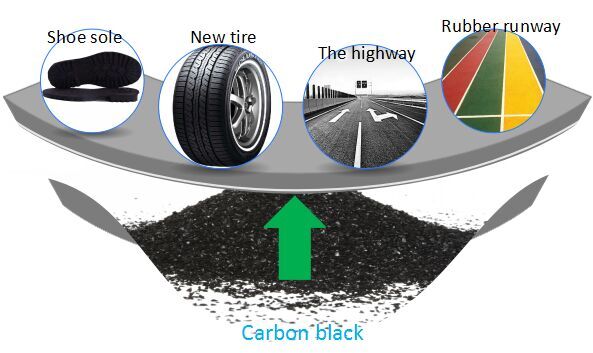

Carbon black usage

2. Carbon black: mainly used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigment manufacturing materials.

3. Steel wire: It is mainly used for recycling and remelting raw materials.

Continuous tire pyrolysis plant will be your best choice !!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com