Plastic is the use of monomer materials to synthesis or condensation reaction of the material. Wide range of plastic, more useful, easy to color, part of the high temperature, and easy processing can be mass-produced, the price is cheap, but a large number of waste plastics also give our living environment caused serious pollution. DoingGroup in order to ease the energy crisis and environmental pollution, developed a waste plastic pyrolysis plant. It is the use of high temperature cracking chemical reactions, the cracking of waste plastics into fuel, carbon black, non-condensable gas process.

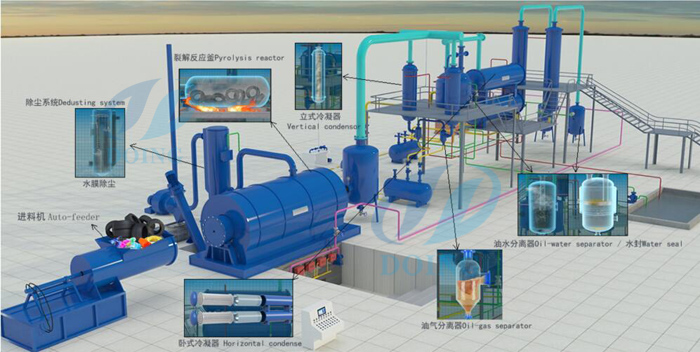

Waste plastic pyrolysis plant, the main workflow:

1. The first plastic push device automatically pushed into the reactor.

2. The reactor was heated at high temperature. Waste plastics cracked into oil and gas.

3. Cracked hydrocarbons through the condensing unit, part of the liquefaction of the fuel into the tank, the other part of the non-condensable gas, after the negative pressure device, will once again through the condensing system, the maximum degree of liquefaction for fuel, increase oil yield.

4. The resulting fuel after dust, deodorant device, you can remove the flue gas and odor combustion of fuel.

5. Wait until the autoclave has cooled to below 40 ° C and remove the carbon black.

Waste plastic pyrolysis plant advantages:

1. Recycling of waste can be achieved, cracked fuel, carbon black, can ease the energy crisis.

2. Using 16mm thick boiler special steel and arc compression head, can withstand high temperature and pressure.

3. Safety devices used oil-water separator, water seal, vacuum device. They can prevent oil and gas, tail gas backflow, provide negative pressure, drainage oil and gas.

4. Pinion rotation device, power is small, do not directly contact the reactor, less heat transfer, not easy to deformation.

Nearly RMB 10,000 can be rewarded for running our equipment in one day, mainly from cracked fuels and carbon black. Waste plastic pyrolysis plant final products have a wide range of uses in life:

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

2. Carbon black: mainly used for pressure ball burning and refined milling, refined powder will be used for new tires, rubber soles, pigment production materials.

3. Combustible gas: combustible gas will be recovered by the system re-use the reactor heating.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com