Waste tire pyrolysis equipment

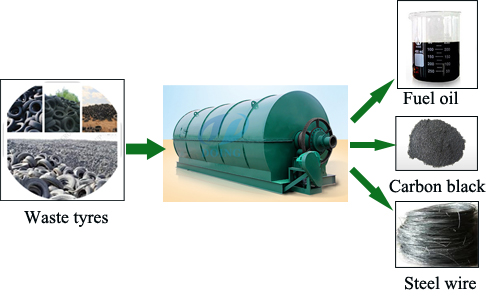

With the improvement of living standards, the car has become one of the essential means of transport for people traveling. On the one hand, it brings great convenience to our life. On the other hand, the waste tires on the car also pose a great threat to our living environment. In response to this serious social problem, DoingGroup uses pyrolysis principle to crack waste tires into fuel oil, carbon black, steel wire and combustible gas. Waste tire pyrolysis equipment by people from all walks of life at home and abroad more and more attention and praise.

Our waste tire pyrolysis equipment is so popular because it has the following advantages:

1. Our pyrolysis reactor is made according to the pressure vessel production standards, using 16mm thick boiler special steel and arc compression head, can withstand high pressure and high temperature.

2. High-standard 3-step welding process, not easy to crack, long service life.

3. Pinion rotation device, power is small, not directly contact the reactor, less heat transfer, not easy to deformation.

4. The three-stage cooling system uses tube condensation, also known as a heat exchanger, and is currently the most commonly used and best performing condenser in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil yield.

5. Our equipment has the following safety devices: water separator, water seal, vacuum device. They can prevent oil and gas from flowing backwards

Waste tire pyrolysis equipment working process

Pyrolysis, refers to the pyrolysis of organic matter in an oxygen-free environment, and is a chemical process that converts one sample to another. Waste tire pyrolysis equipment is the process of pyrolysis of waste tires into oil, non-condensable gases and carbon black and steel wire by heating at high temperatures.

The final product of waste tire pyrolysis equipment is fuel oil, carbon black, steel wire and combustible gas. These materials have a wide range of uses in our life and can be used in a variety of industries.

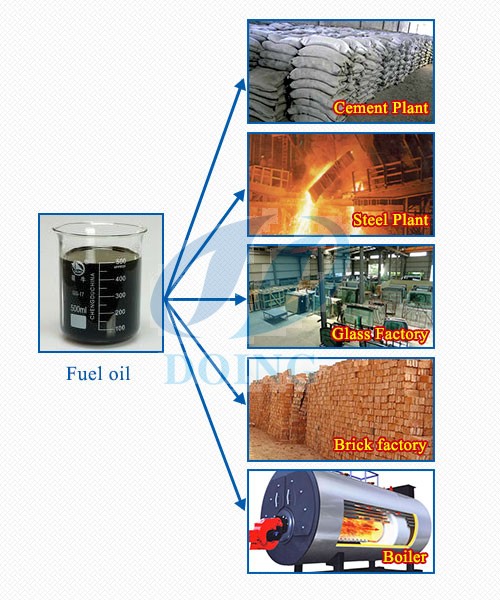

Fuel oil application

Fuel oil : Can be used in steel mills, cement plants, boiler heating, heavy oil generator combustion heating.

Carbon black application

Carbon black: can be used for pressure ball burning, and refining flour. Which refined flour and can be used for new tires, rubber soles, pigments of raw materials.

Steel wire: Can be used for scrap recycling and re-casting.

Combustible gas: will be recycled back to the equipment for reactor heating.

Our waste tire pyrolysis equipment has different specifications, designed for each customer's different needs of different capacity, customers can choose according to their needs and budget. Any questions about the machine, please feel free to contact us!!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com