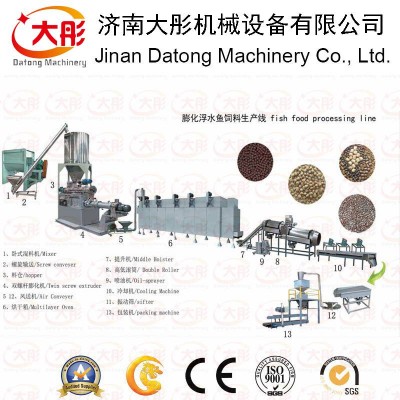

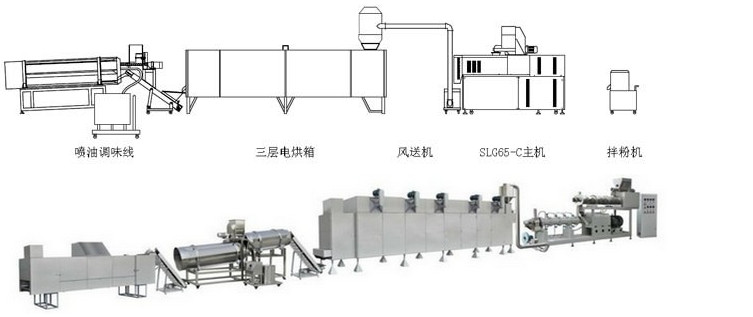

CE Certified Chinese Supplier Fish Feed Pellet Production Line 1.Product Description:This fish feed production line is newly developed to meet the demand of intensive production of fish feed pellets.With many specifications this production line can produce floating fish feed, sinking fish feed etc. The products can have different shapes, unique flavor, rich,nutrients and fine texture to meet the different eating habit of fish.Super automation control and high production efficiency, our fish feed production line is the best choice for medium and big sized feed mills and breeding farms. Our fish feed production line can produce various kinds of pellets for different varieties of fishes including Halibut pellets, Catfish pellets, Trout pellets,Hemp pellets, etc.

2.Advantages of Fish Feed Pellet Production Line

1. )Advanced technology, high capacity and low energy consumption.

2. )The feed pellet line occupies less floor space and needs low investment in construction work. The modular structure is convenient for assembly and disassembly, facilitating the shipment and installation.

3. )alarm device is available. The operation is simple and convenient.

4. )Wide applicable scope: The plant can produce both floating ,applicable for fish farm holders and fish feed manufacturers.

3.Material grinding---- feed hammer mill

Raw material ingredients should be grinded to the required size by feed grinder. We supply two types of feed grinders to meet your different requirements;Hammer Mill is suitable for small or medium sized feed extruding factories; Fine feed Hammer Mill, is mainly applied to fine grinding of meals, special aquatic feed.

4.Material mixing---feed mixer

Mixing the material thoroughly can ensure extruding efficiency and improve the feed quality. We supply two kinds of feed mixers for you to choose: double-shaft efficient mixer can be applied to mixing powdery,granular, flaky and blocky materials while feed ribbon type mixer is mostly used for mixing powdery materials.These two kinds of mixers can be customized with atomizing spraying system which will add liquid like molasses and grease to material more evenly.

5.Extruding process--- floating feed pellet extruder

Our fish feed pellet machine can be divided into two types: dry type fish feed machine and wet type feed machine. The wet type is with the conditioner and need to equip the steam boiler. The dry type fish feed extruder is cheaper while the capacity of the wet type fish

feed extruder is higher, so usually the wet type fish feed extruder is suitable for large feed pellet factory and the dry type fish feed extruder is better and economic for the small and medium size user or factory.

![Ce Certified Chinese Supplier Fish Feed Pellet Production Line]()

![Ce Certified Chinese Supplier Fish Feed Pellet Production Line]()

![Ce Certified Chinese Supplier Fish Feed Pellet Production Line]()

![Ce Certified Chinese Supplier Fish Feed Pellet Production Line]()

6.Packing process - Pellet packing machine

After cooling process, the wood pellets will not directly enter into the feeding process, avoiding the wood pellet affected with damp, the packing process is very necessary. The packing process is effectively handled by our Semi-Auto Packing Machine.

![Ce Certified Chinese Supplier Fish Feed Pellet Production Line]()

7. Fish Feed Pellet Payment term:

1. )Loading quantity: : The above machines requires 2*40' container.

2. )Delivery time: within 30 days after receiving deposit.

3. )Period of validity of the price: in 3 months.

4. )Payment Terms : 30% by T/T as deposit, the balance against the copy of B/L.

8.FAQ:

1). Your products have a warranty?

Yes, we have one year warranty period, if there are quality problem, we can give you a free replacement

2). Will I be able to customize our products from your factory?

Yes, we can produce products according to your requirements.Please give me you want machinery equipment specifications and drawings.

3). Can you give me a discount?

Discount need according to different conditions.More orders, more discount you can enjoy the factory equipment for sale.

4). How do you shipping the finished product?

by sea,By plane,by Courier service.DHL, UPS, TNT, etc.

9.Customer visiting & about me:

We sincerely welcome you and your team visit our factory, it will be highly appreciated if you can bring sample to us, we will let our technician test machine for you accordingly.

Any inquiry or Interests, Please feel free to contact Sales in Jinan Datong machinery & equipment Co., Ltd.

You can click below to send Inquiry to me, I will reply you asap.

English

English