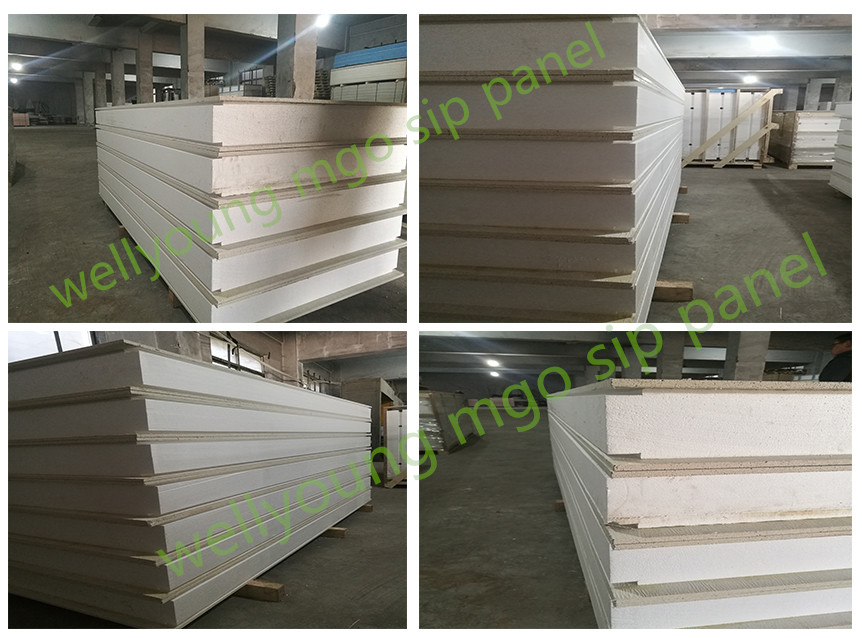

fast construction mgo sandwich panel for prefab house

Structural insulated panels (SIPs) are a high performance building system for residential and commercial construction. The panels consist of an insulating foam core sandwiched between two structural facings, typically Magnesium Oxide Board (MGO) for walls, roofs and floors in new residential and commercial buildings.

Structural insulated panels (SIPs) are a high performance building system for residential and commercial construction. The panels consist of an insulating foam core sandwiched between two structural facings, typically Magnesium Oxide Board (MGO) for walls, roofs and floors in new residential and commercial buildings

Size: 4'x8' / 4'x9' / 4'x10' (Feet)

1200mm x 2400mm / 1200mm x 270mm / 1200mm x 3000mm)

Thickness:

75mm / 100mm / 120mm / 150mm

Advantages

1. Excellent Thermal Performance

WELLYOUNG MgO SIP Structural Insulated Panels provide superior thermal performance, which will last the life span of the building. This is due to the solid core of Expanded Polystyrene (EPS) or Extruded Polystyrene (XPS)

insulation throughout the structure which ensures that the building is heated evenly, remains free from cold spots and will benefit from reduced heating costs.

WELLYOUNG MgO SIP (Structural Insulated Panels) are pre-engineered in a factory environment which results in less defects and wastage throughout the manufacturing and construction processes.

Using specialist in-house 3D CAD software, WELLYOUNG MgO SIP (Structural Insulated Panels )can be designed to accommodate a wide variety of building applications.

4. Habitable Roof Space:

WELLYOUNG MgO SIP Building Systems do not require roof trusses, therefore providing an additional habitable room in the roof.

SIPs are prefabricated systems used primarily for walls and roofs. SIPs employ composite materials, reduce waste through modular construction methods, achieve high insulation values, and may be used instead of many conventional building methods.

Comparsion of Core:

| Core | Advantage | Disadvantage |

| Polyurethane | The main advantage of polyurethane (or the much harder to pronounce derivation, polyisicyanurate) is that it has the highest R-value of any SIP panel. After what's called thermal drift, it's about 6 to 6.8 of R-value per inch of panel. | The main detractor of urethane panels is the high cost. The other disadvantage in terms of construction is that polyurethane has a high melting point, hot wire burners (the primary method of modifying EPS and XPS panels on site) can't be used. |

| EPS | Over 80% of the SIP panels installed are EPS. EPS core material is widely available. It is easy to modify on sight and most sip installers have experience dealing with EPS. It's also the least expensive option in terms of material cost. | |

| XPS | XPS has many of the best characteristics of both polyurethane and EPS. It has a high R-value (5 R-value per inch of panel). It is dense and stable yet has a relatively low melting point so on-site modifications are as easy as EPS. Also, like EPS, it bonds easily to OSB and gypsum board. | Unfortunately XPS is expensive and manufactured panels are not widely available |

Packaging & Shipping