Product Description

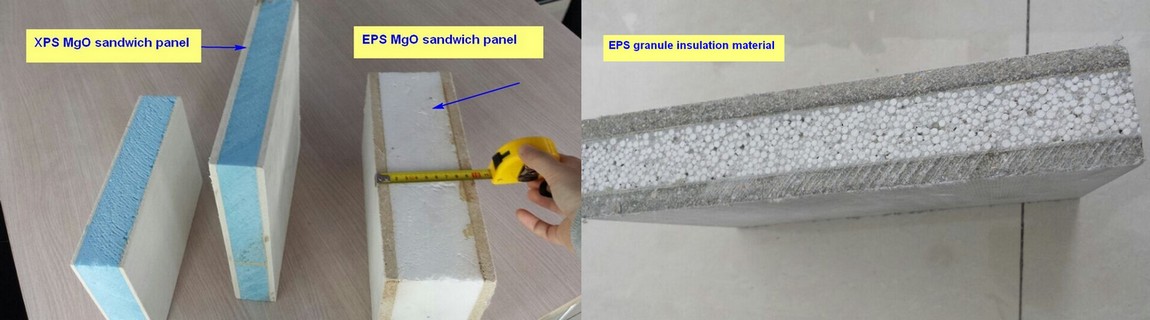

MgO Sandwich panel is a composite building material. They consist of a sandwich of two layers of structural board with an insulating foam in between. Panel skins are magnesium oxide boards. Insulation core can be Expanded Polystyrene(EPS), Extruded Polystyrene(XPS).

Compose : MgO (Magnesuim oxide ) Board +EPS/XPS +MgO (Magnesuim oxide ) Board

Size: 4'x8' / 4'x9' / 4'x10' / 4'x16' / 4'x20' (Feet)

1200mm x 2400mm / 1200mm x 270mm / 1200mm x 3000mm)

Thickness: 4.5" / 6.5" / 8.25" / 10.25". (Inch)

114mm / 165mm / 209mm / 260mm

Types of spline: Dimension lumber, OSB, Light Gauge Steel

Advantages

Advantages to use SIPs

Architectural Benefits

High quality construction method.

Comfortably warm, clean, and quiet.

Cost Benefits

Equal or lower first costs.

Lower long term operating costs.

Incentives available from utility service provider for energy efficient design.

Lower maintenance costs for you.

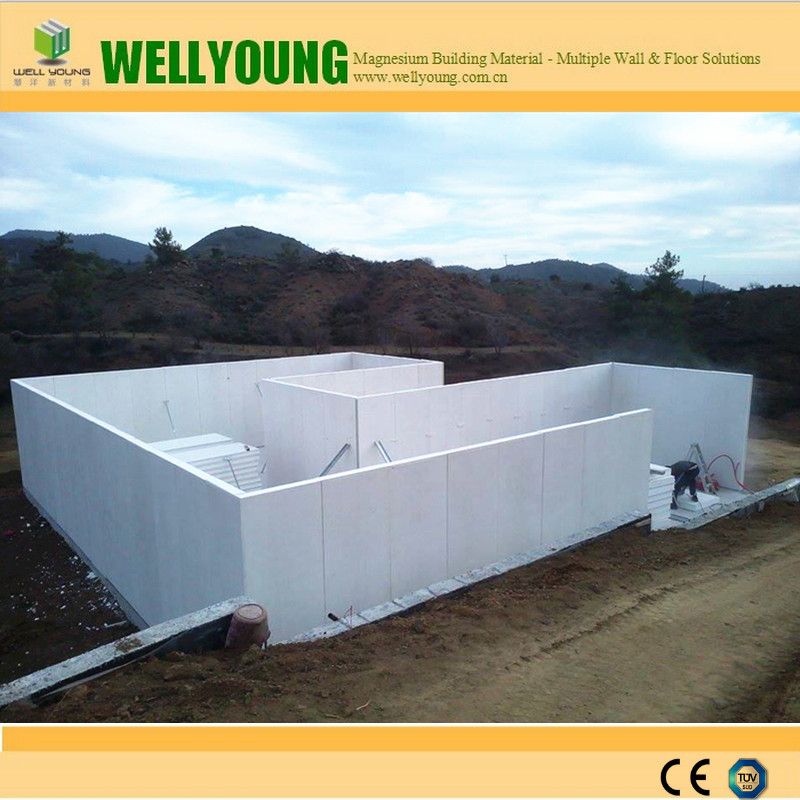

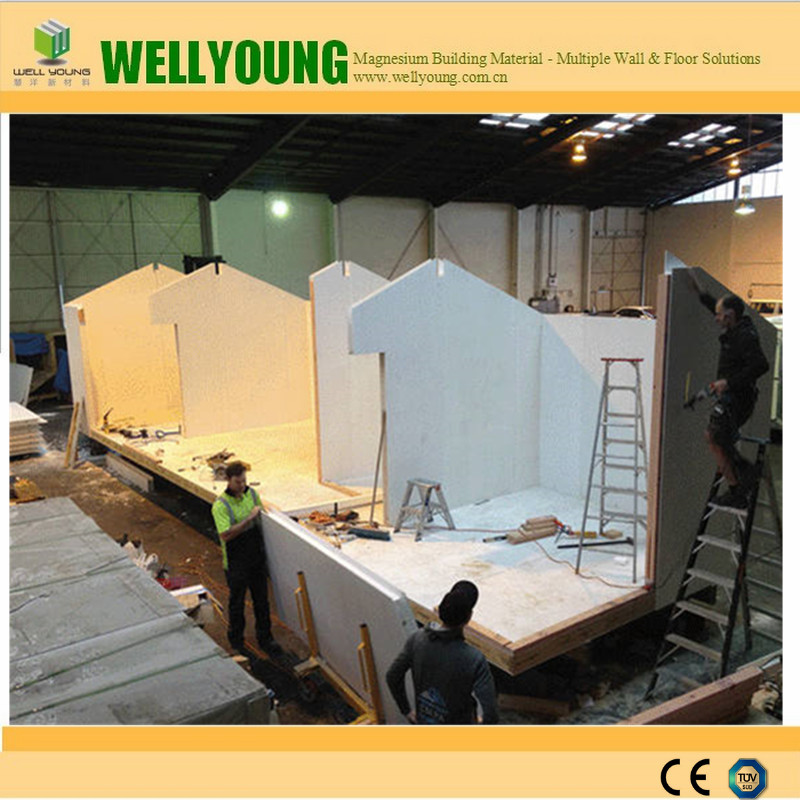

Construction Process Benefits

Easy to construct, with short learning curve.

60% shorter construction time

Quick turnaround time for greater satisfaction.

Increased builders production capacity.

Environmental Benefits

50% less framing lumber.

50% more energy efficient.

Requires less room at building site (less site disturbance).

Less construction waste.

SIPs are prefabricated systems used primarily for walls and roofs. SIPs employ composite materials, reduce waste through modular construction methods, achieve high insulation values, and may be used instead of many conventional building methods.

Comparsion of Core:

| Core | Advantage | Disadvantage |

| Polyurethane | The main advantage of polyurethane (or the much harder to pronounce derivation, polyisicyanurate) is that it has the highest R-value of any SIP panel. After what's called thermal drift, it's about 6 to 6.8 of R-value per inch of panel. | The main detractor of urethane panels is the high cost. The other disadvantage in terms of construction is that polyurethane has a high melting point, hot wire burners (the primary method of modifying EPS and XPS panels on site) can't be used. |

| EPS | Over 80% of the SIP panels installed are EPS. EPS core material is widely available. It is easy to modify on sight and most sip installers have experience dealing with EPS. It's also the least expensive option in terms of material cost. | |

| XPS | XPS has many of the best characteristics of both polyurethane and EPS. It has a high R-value (5 R-value per inch of panel). It is dense and stable yet has a relatively low melting point so on-site modifications are as easy as EPS. Also, like EPS, it bonds easily to OSB and gypsum board. | Unfortunately XPS is expensive and manufactured panels are not widely available |

R Value of SIPs

| Panel Thickness | EPS Core | R-Value | U-Value |

| 4 1/2’’ (115mm) | 3 5/8’’ (92mm) | 16 | 0.355 |

| 6 1/2 (165mm) | 5 5/8’’ (143mm) | 24 | 0.237 |

| 8 1/4 (210mm) | 7 3/8’’ (187mm) | 33 | 0.172 |

| 10 1/4 (260mm) | 9 3/8’’ (238mm) | 40 |

0.142 |

| 12 1/4 (311mm) | 11 3/8’’ ( 289mm)’’ | 49 |

0.116 |

Panel weight table:

| 4' x 8' Ft | 4' x 10' Ft | |

| 4.5" Inch | 45kg | 56.25kg |

| 6.5" Inch | 47.5kg | 59kg |

| 8.25 Inch | 50kg | 62.5kg |

| 10.25Inch | 52.5kg | 66kg |

Packaging & Shipping